Drilled Shaft Foundations: Expertise and Applications

Durable and Dependable Solutions for Challenging Soil Conditions

At Tri-State Drilling, we are recognized as a leader for providing high-capacity drilled pier services, also known as drilled shafts, caissons, bored piles, or cast-in-drilled-hole (CIDH) piles. Our team ensures your project stands on a foundation designed for ultimate strength and reliability. With cutting-edge techniques and equipment, we offer customized deep foundation solutions to meet your unique project requirements.

Versatile Applications

Structural Support

Ideal for supporting buildings, bridges, substation equipment, towers, and tanks.

Slope Stabilization

Ensures stability on slopes and embankments.

Earth Retention

Ideal for soldier pile that requires a “drill & set” approach while backfilling with a lean concrete mix.

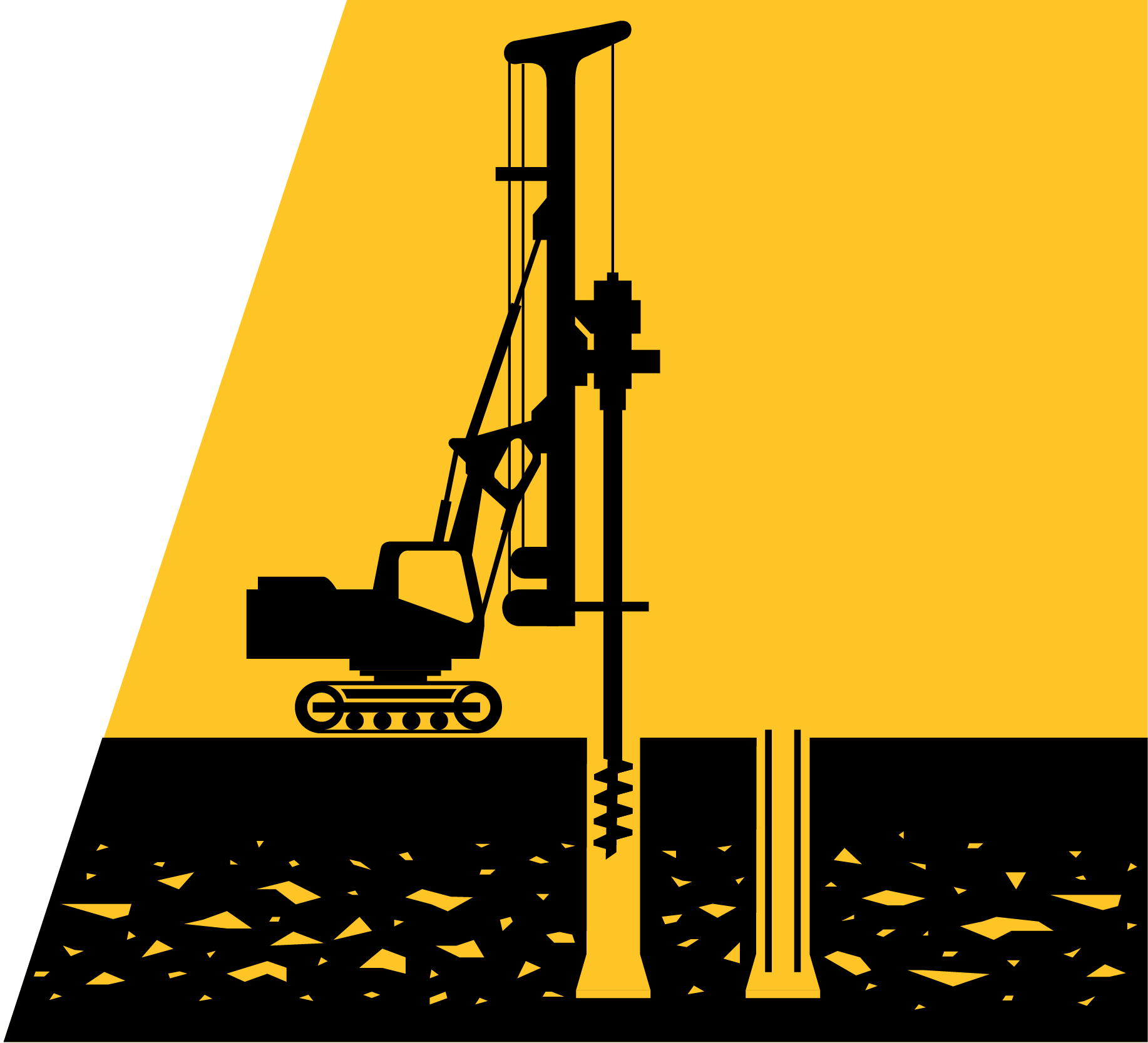

Drilled Pier Installation

Drilled pier foundations are installed through various methods, including dry (open hole), stabilizing polymer slurry, or steel-cased techniques. Permanent casing is used in corrosive environments or when drilling through water, while temporary casing may be necessary in adverse subsurface conditions.

Typical Project Stages:

Drilling: A hole is excavated to the design diameter & depth using augers, core barrels, or specialized tooling & casing.

Cleaning and Inspection: The hole is cleaned out and inspected using manual methods or advanced tools like Mini-SID or down-hole cameras.

Reinforcement: We furnish and install steel cages with centralizers, if required.

Concrete Placement: Concrete is placed either by freefall or tremie methods.

Casing Removal: Temporary casing is withdrawn, leaving a completed shaft capable of resisting compressive and lateral loads and uplift forces.

Key Benefits

Versatility

Wide range of equipment and tooling for virtually any condition.

Experienced Construction

Proficient in both dry and wet shaft construction methods.

Limited Access Capability

Able to construct drilled shafts in low headroom and restricted access areas.

Variable Diameters

Capable of drilling shafts ranging from 24 to 240 inches in diameter.

In-House Manufacturing

We design, build, repair, maintain, and modify our equipment and tools.

Adaptability

Capable of completing alternate foundation systems if project conditions change.

Wide Variety of Applications

Suitable for most structures, including buildings, tanks, towers, substations, and bridges.

Quality Assurance

Non-destructive test methods ensure the quality of concrete throughout the shaft length.

Innovative Solutions for Stable Foundations

Tri-State Drilling uses state-of-the-art equipment and proprietary drilling tools to meet specific site constraints, such as limited access and low overhead conditions. We conduct rigorous load testing to verify the load-carrying capacity and quality of subsurface materials, using methods like Osterberg Cell (O-Cell), direct static testing, and statnamic testing for both compressive and lateral loads.

Discover the strength and reliability of Tri-State Drilling’s drilled pier solutions. Contact us today to learn more about our drilled shafts and how we can support your next project with our expert foundation services.